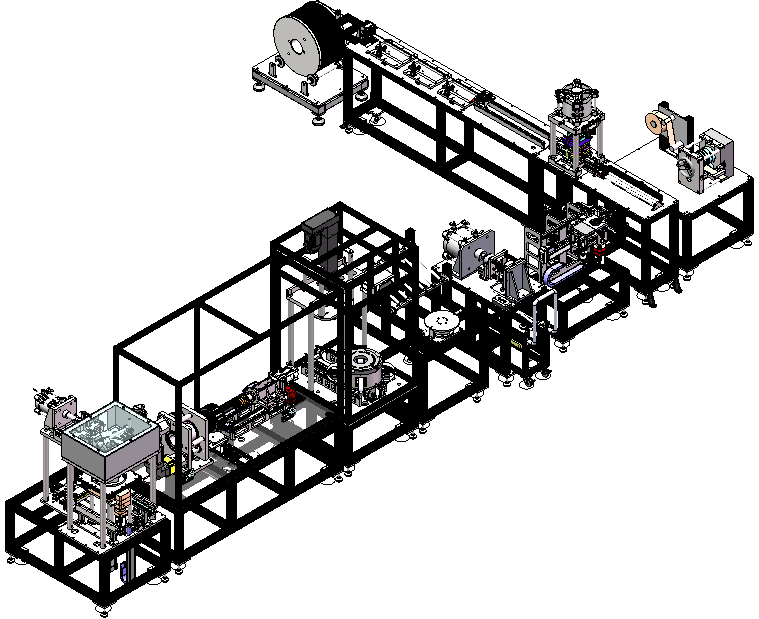

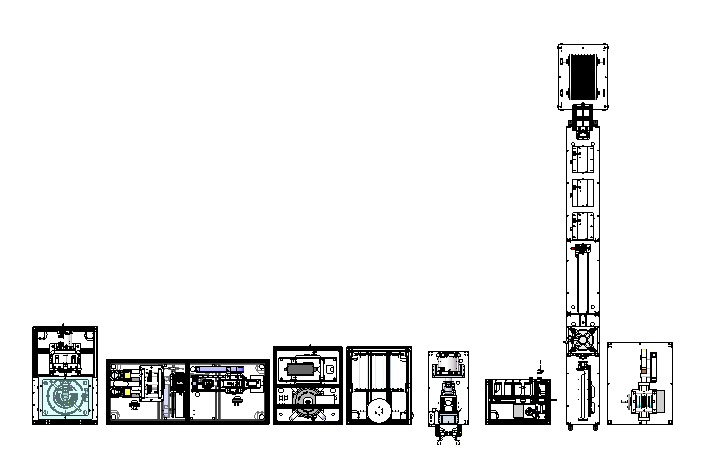

; Assembly:

1. Folding: Insulation paper pre folded

2. Straightening: Straighten the coil copper wire

3.2D forming: 2D bending of copper wire

4. 3D forming: 3D bending of copper wire

5. Manual insertion of wires: Manually insert copper wires into the stator

6. Winding pressing: The servo press presses the copper wire into the stator

7. Twisting: Twist the head of the copper wire winding

8. Cut flat: Cut the copper wire flat

9. Welding: For copper wire welding: (cooperative manufacturer)

Scope:

Samples can be made for flat wire I-PIN, HIR-PIN motors 48 and 72 slots 6-10 layers for trial production