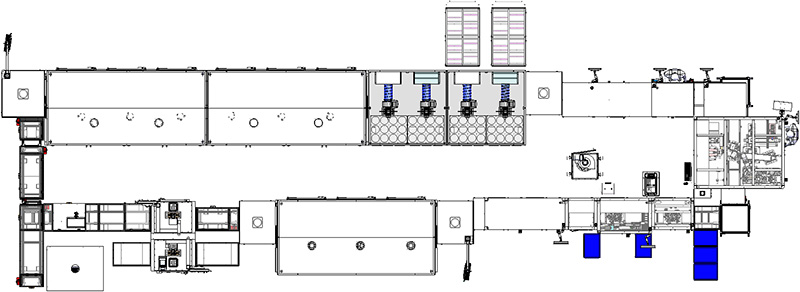

Assembly:

1. Manual feeding

2. Robot welding (replacing manual hazardous operations)

3. Manual assembly

4. Laser coding (engraving the product's independent QR code+number)

5. The automatic screwing machine locks the product housing (precise positioning, controllable torque)

6. Preheating the product with a preheating furnace (before pouring glue, the product is heated with a preheating furnace to improve the fluidity of the glue in the product cavity and facilitate penetration and filling of various gaps in the product cavity)

7. Vacuum gluing (solves the problem of bubbles in the glue, allowing the glue to be filled uniformly, with a flat surface and complete internal filling)

8. High temperature furnace curing (accelerating the effect of adhesive curing)

9. Cooling furnace (quickly reducing product temperature)

10. Manual cutting

Detection:

Voltage resistance and insulation testing, visual inspection, resistance testing, airtight leakage testing, and final product testing

All workstations are controlled by PLC, interchangeable, and each job process has MES traceability function