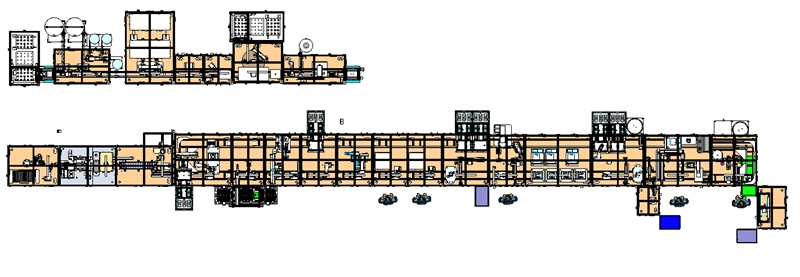

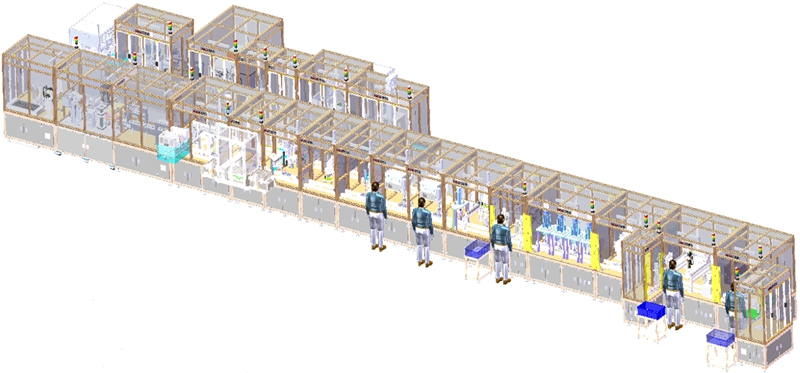

Assembly:

First, stator assembly:

1. Loading of stator core and assembly of wire bridge

2. Winding machine

3. Manual wire cutting and installation of copper bars

4. Mechanical arm copper bar welding

5. Shell coding and pressing installation

6. Coating the outer shell with oil and assembling the bearings

7. Flow to the electro-hydraulic machine assembly

Secondly, rotor assembly:

1. Mechanical arm picking and assembly+manual loading and assembly

2. Press the rotor shaft into the rotor core and magnetize the rotor

3. Press the bearings at both ends of the rotor into place

4. Flow to the motor assembly station

Third,Motor Assembly:

1. The mechanical arm takes and assembles the rotor assembly with the stator assembly through manual loading and assembly

2. Pressing

3. The controller is installed on the motor body

4. Lock the product housing with a screw driver

5. Flow to the electro-hydraulic pump assembly

Fourth,Electrohydraulic pump assembly:

1. Mechanical arm picking and assembly+manual loading and assembly

2. Three axis glue dispensing machine

3. Cover plate pressing

4. Laser marking

5. Screw machine locking product housing

Detection:

Compression force displacement, UVW detection, stator detection, gap detection, airtightness testing, resistance detection, performance testing

All workstations are controlled by PLC, interchangeable, and each job process has MES traceability function