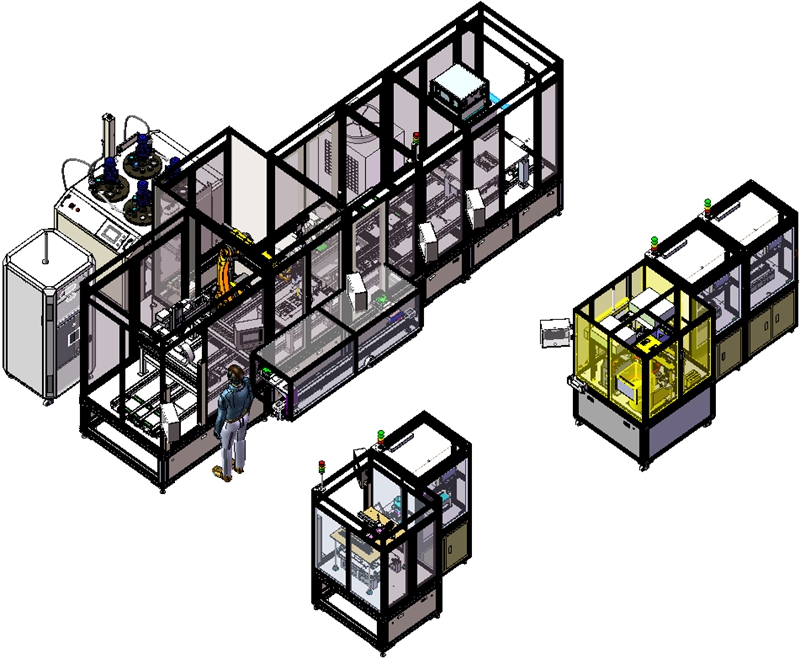

Assembly:

1. The product flows from the previous process to this production line

2. Three axis vacuum gluing (solves the problem of bubbles in the glue, allowing the glue to be filled uniformly, with a flat surface and complete internal filling)

3. Applying glue to the robotic arm (sealing the gaps between the product shells)

4. The mechanical arm takes and assembles (replacing the heavy labor of the operator)

5. The automatic screwing machine locks the product housing (precise positioning, controllable torque)

6. Flow to the next stage of the process

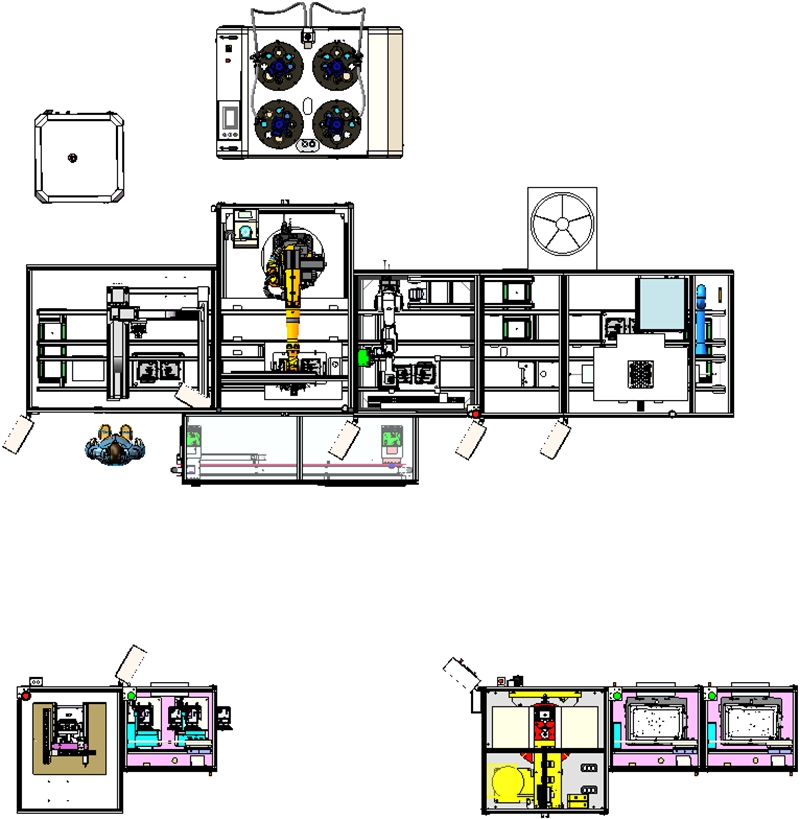

Detection:

Visual inspection, resistance detection, airtight leakage testing

All workstations are controlled by PLC, interchangeable, and each job process has MES traceability function