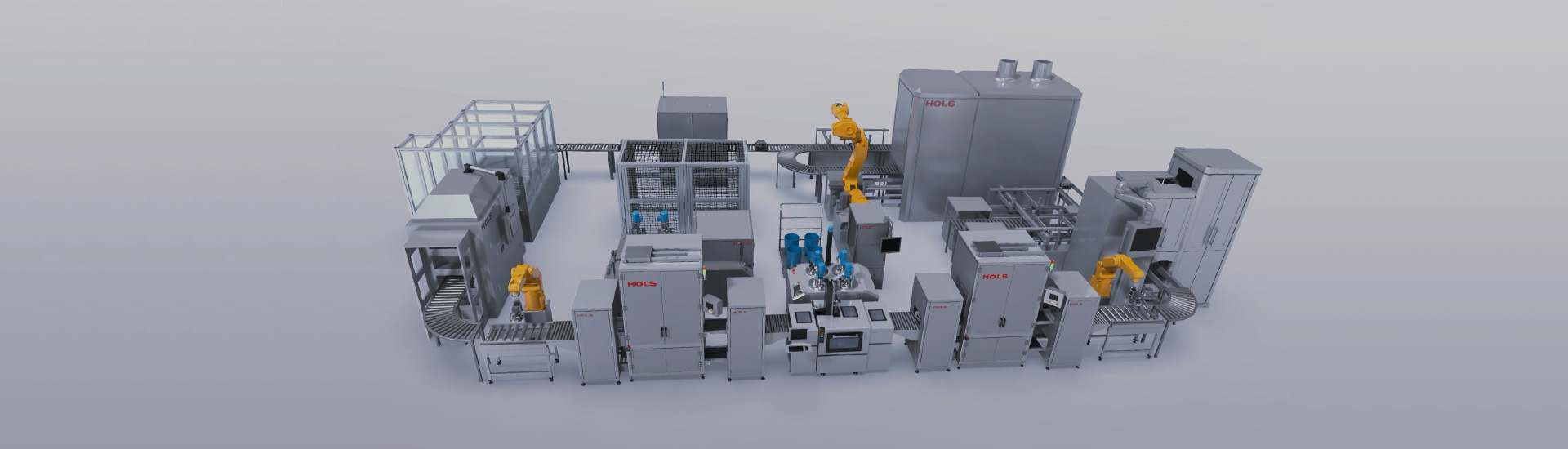

To meet the demands of potting complex components and enhance product quality, Hols developed a Vacuum Potting System utilizing a three-stage vacuum chamber for potting processes. This design ensures the core potting stages remain continuously under vacuum condition, significantly reducing cycle time (by eliminating repeated vacuum pumping/venting) and boosting production capacity, making it a cost-effective solution for high-volume manufacturing. The system is specifically optimized for fast and precise potting of small to medium-sized components.