What are the common problems with fully automatic glue dispensers

View count:2023-04-26 View count:1951

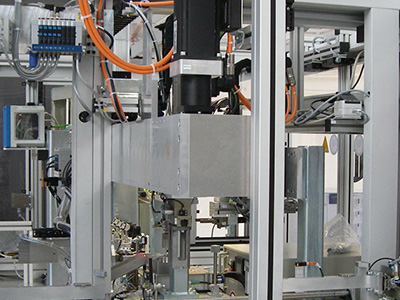

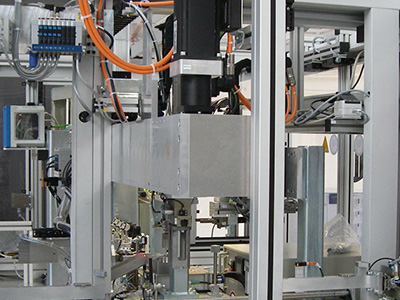

With the development of the economy, distributors are widely used in industries such as electronics, lighting,

automotive, industrial electrical, solar photovoltaic, and construction engineering. The most common problem with fully

automatic glue dispensers is valve problems. The following are effective methods for solving common problems when using

glue valves:

1. Oral blockage

Reason: The needle holes of the fully automatic glue filling machine were not completely cleaned, and impurities were mixed into the chip, resulting in clogging of the holes. Incompatible adhesives were mixed, resulting in low or no adhesive output

Solution: Replace the clean needle, replace the high-quality patch, and ensure that the brand number of the patch is correct

2. Rubber valve leakage

Reason: The needle diameter used in the fully automatic glue filling machine is too small. A needle that is too small will affect the exhaust bubble action of the rubber valve when it starts to be used, affecting liquid flow and causing back pressure. As a result, the rubber valve will leak soon after it is closed

Solution: Replacing the large needle can solve this problem. In addition, the air in the liquid may leak after the rubber valve is closed. It is best to remove the air in the liquid in advance, or use rubber that is not easily prone to bubbles, or centrifuge the rubber before use

3. The flow rate is too slow

Reason: The pipeline of the fully automatic glue dispenser is too long or too narrow, the air pressure at the nozzle is insufficient, and the dispensing flow rate is too slow

Solution: Change the distributor pipeline from 1/4 to 3/8, the shorter the pipeline, the better. In addition, improve the rubber port and air pressure, and accelerate the flow rate

4. There are bubbles in the fluid

Reason: The excessive fluid pressure and short valve opening time of the distributor may cause air to seep into the liquid and produce bubbles

Solution: Reduce fluid pressure and use a tapered needle

5. The size of the glue is inconsistent

Reason: The pressure cylinder and air pressure of the fluid stored in the fully automatic glue filling machine are unstable, and the glue is uneven and of different sizes

Solution: Do not insert pressure into the low-pressure section of the pressure gauge. The control pressure of the rubber valve should be at least 60psi or above to ensure the stability of the rubber. Finally, check the dispensing time. The dispensing is unstable within 15/1000 seconds, and the longer the dispensing time, the more stable the dispensing becomes

The above content is about the common causes and solutions of faults in fully automatic glue filling machines, and I believe everyone is aware of it. The common problems of automatic distributors can be large or small, and users can quickly solve these problems as long as they master the correct solutions.

1. Oral blockage

Reason: The needle holes of the fully automatic glue filling machine were not completely cleaned, and impurities were mixed into the chip, resulting in clogging of the holes. Incompatible adhesives were mixed, resulting in low or no adhesive output

Solution: Replace the clean needle, replace the high-quality patch, and ensure that the brand number of the patch is correct

2. Rubber valve leakage

Reason: The needle diameter used in the fully automatic glue filling machine is too small. A needle that is too small will affect the exhaust bubble action of the rubber valve when it starts to be used, affecting liquid flow and causing back pressure. As a result, the rubber valve will leak soon after it is closed

Solution: Replacing the large needle can solve this problem. In addition, the air in the liquid may leak after the rubber valve is closed. It is best to remove the air in the liquid in advance, or use rubber that is not easily prone to bubbles, or centrifuge the rubber before use

3. The flow rate is too slow

Reason: The pipeline of the fully automatic glue dispenser is too long or too narrow, the air pressure at the nozzle is insufficient, and the dispensing flow rate is too slow

Solution: Change the distributor pipeline from 1/4 to 3/8, the shorter the pipeline, the better. In addition, improve the rubber port and air pressure, and accelerate the flow rate

4. There are bubbles in the fluid

Reason: The excessive fluid pressure and short valve opening time of the distributor may cause air to seep into the liquid and produce bubbles

Solution: Reduce fluid pressure and use a tapered needle

5. The size of the glue is inconsistent

Reason: The pressure cylinder and air pressure of the fluid stored in the fully automatic glue filling machine are unstable, and the glue is uneven and of different sizes

Solution: Do not insert pressure into the low-pressure section of the pressure gauge. The control pressure of the rubber valve should be at least 60psi or above to ensure the stability of the rubber. Finally, check the dispensing time. The dispensing is unstable within 15/1000 seconds, and the longer the dispensing time, the more stable the dispensing becomes

The above content is about the common causes and solutions of faults in fully automatic glue filling machines, and I believe everyone is aware of it. The common problems of automatic distributors can be large or small, and users can quickly solve these problems as long as they master the correct solutions.