What are the advantages and performance characteristics of automatic glue dispensers

View count:2021-11-29 View count:560

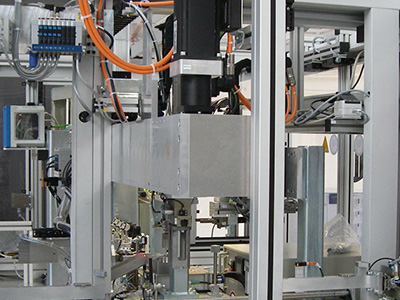

With the development of industrial production, in order to improve production efficiency, many enterprises are starting

to use automatic glue filling machines. The automatic glue pouring machine adopts an automated operation form, reducing

the manual pouring process. What are the advantages of automatic glue dispensers? What is its device performance? Let's

introduce to you the following:

First,The advantages of automatic gluing machine:

1. An automated mobile platform, with high efficiency in mixing and dispensing glue, and higher accuracy and automation compared to traditional gluing processes

At the same time, the device also adopts computer programming control, with a high degree of intelligence. It adopts a touch type Chinese operation interface, which is simple and easy to operate. Can store 30 sets of glue parameters, and the same workpiece does not need to be reset

3. The glue amount, thickness, coating speed, dispensing time, and stopping time can all be set as parameters, with stable glue output and no leakage of glue

4. Automatic glue dispensers can effectively save labor, with a single device capable of producing up to 5-6 traditional people

5. The automatic glue filling machine can be used for on-demand mixing, achieving simultaneous glue filling while mixing, greatly saving glue water

6. Dual barrel design, A glue and B glue are stored separately, ensuring that the glue does not solidify when left for a long time. Using dynamic or static mixing to achieve uniform and thorough mixing

Secondly, the equipment performance of the automatic glue filling machine

1 Equipment Usage: It can be suitable for various types of glue and can be freely dispensed with various amounts. The glue dispensing ratio and dispensing speed can be freely set by the touch screen

2 Adopting a volumetric metering steel loading pump that is not affected by changes in the viscosity of the material liquid, it can achieve stable and high-precision metering and dispensing

3 When the glue contains hard fillers, a pump is used to ensure that long-term use does not affect the accuracy and ratio of dispensing

4 When selecting dynamic mixing, a new type of mixer is used, and multi-layer stirring paddles are used for forced mixing to ensure uniform mixing

5 Adopting dual servo drive, A agent pump and B agent pump are respectively driven by a servo motor, with reserved signal interfaces, which can be directly connected to automation equipment such as robotic arms

6 The overall equipment design is compact, and the operation is simple and convenient.

First,The advantages of automatic gluing machine:

1. An automated mobile platform, with high efficiency in mixing and dispensing glue, and higher accuracy and automation compared to traditional gluing processes

At the same time, the device also adopts computer programming control, with a high degree of intelligence. It adopts a touch type Chinese operation interface, which is simple and easy to operate. Can store 30 sets of glue parameters, and the same workpiece does not need to be reset

3. The glue amount, thickness, coating speed, dispensing time, and stopping time can all be set as parameters, with stable glue output and no leakage of glue

4. Automatic glue dispensers can effectively save labor, with a single device capable of producing up to 5-6 traditional people

5. The automatic glue filling machine can be used for on-demand mixing, achieving simultaneous glue filling while mixing, greatly saving glue water

6. Dual barrel design, A glue and B glue are stored separately, ensuring that the glue does not solidify when left for a long time. Using dynamic or static mixing to achieve uniform and thorough mixing

Secondly, the equipment performance of the automatic glue filling machine

1 Equipment Usage: It can be suitable for various types of glue and can be freely dispensed with various amounts. The glue dispensing ratio and dispensing speed can be freely set by the touch screen

2 Adopting a volumetric metering steel loading pump that is not affected by changes in the viscosity of the material liquid, it can achieve stable and high-precision metering and dispensing

3 When the glue contains hard fillers, a pump is used to ensure that long-term use does not affect the accuracy and ratio of dispensing

4 When selecting dynamic mixing, a new type of mixer is used, and multi-layer stirring paddles are used for forced mixing to ensure uniform mixing

5 Adopting dual servo drive, A agent pump and B agent pump are respectively driven by a servo motor, with reserved signal interfaces, which can be directly connected to automation equipment such as robotic arms

6 The overall equipment design is compact, and the operation is simple and convenient.